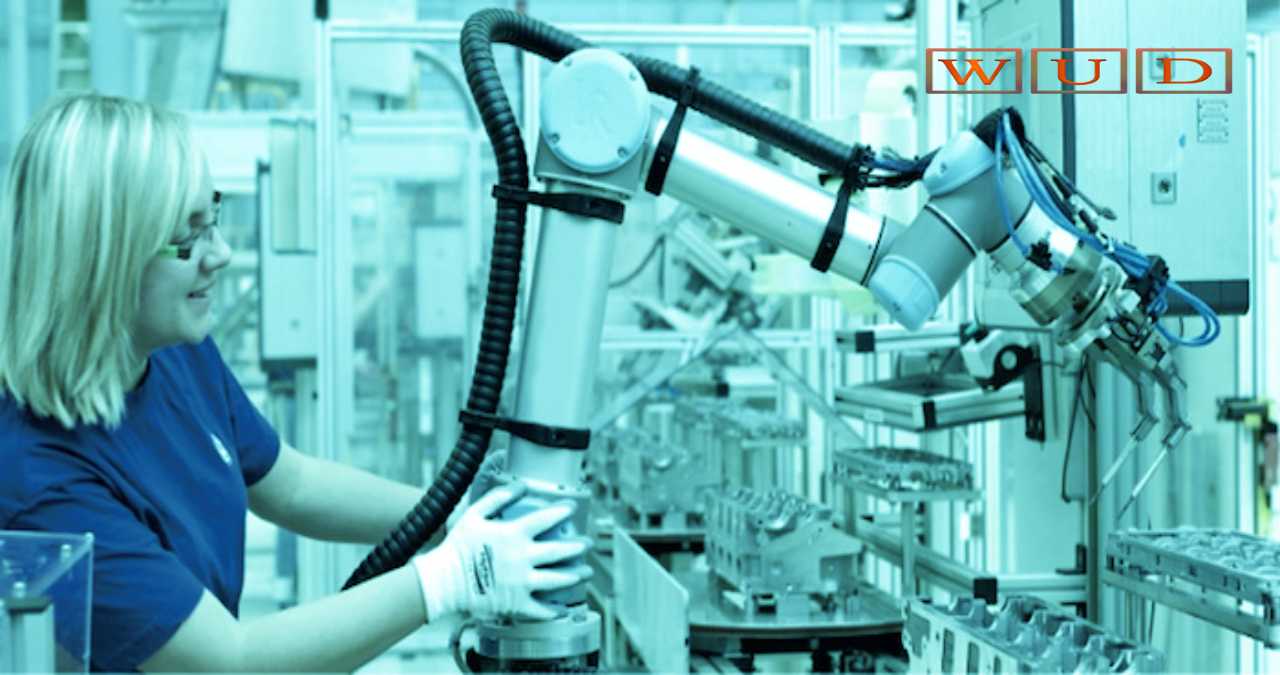

The Advantages Of Collaborative Robots In The Industry

The evolution within the world of robotics has allowed companies to be much more competitive. The use of robots within the industry allows them to be more productive since they greatly facilitate the actions of operators. Although some robots are manufactured and programmed to work on their own, it is through the use of collaborative robots that productivity is improved.

Benefits of using collaborative robots in industry

The industrial robotics offers the opportunity for operators to perform tasks that would otherwise be more difficult to perform and offers clear advantages such as:

Fewer work accidents

Thanks to the use of these robots in the industry, fewer workplace accidents occur. The reason is quite simple and is that these robots end up being exposed to the most dangerous tasks, instead of workers. In addition to considerably reducing the most serious accidents, they have also greatly reduced the most common injuries, such as bone or muscle injuries due to effort, since obviously, a robot does not suffer from these problems.

Likewise, for their manipulation with toxic or dangerous substances, robots are a great solution to avoid exposing the worker to this series of risks. All this, we must always remember that it is being carried out through the use and supervision of the robot itself by an operator, the robot is never doing it on its own. The operator acts as a guide and uses the robot as a tool, making it much more efficient, increasing its performance by up to 85% because it is not fatigued and also has fewer physical limitations.

The mix of strength and decision

A collaborative robot has many more advantages than a traditional robot. To the classic strength and endurance by which a conventional robot is characterized, we have to add the rationality and decision – making capacity of the person who is using it. This added value that is added to this robot helps to a great extent to improve the automation of processes within the industry.

Another advantage that these robots have is that being constantly guided by humans, they do not need complex programming to work, making them much easier to program, they end up being more accessible and, therefore, much cheaper. Thanks to this simplicity, it is much easier to incorporate them into any factory, since they can be adapted without any problem.

In short, the world of robotics is constantly evolving to offer us robots that interact with the operators, allowing easy integration into production processes. These robots provide many solutions to the industrial landscape, thereby managing to end many problems that this had, achieving a much more efficient and also more productive environment for the worker. The collaborative robots are a tailored solution, available to any company.